Recently, at the 2nd World Hydrogen Industry Expo held in Guangzhou, EVE Hydrogen launched the "Monkey King" series AEM (Anion Exchange Membrane) hydrogen production system, leading the new future of the AEM electrolysis hydrogen industry.

At the launch event, EVE Hydrogen's Product Manager, Cai Gui Han, stated that under the dual drive of carbon peak and carbon neutrality, hydrogen energy, as a strategic resource for energy transition, has unlocked new codes for the modern energy system. However, in the diversified hydrogen application scenarios, there have always been two major pain points for end users: difficult equipment maintenance and high electricity costs.

The "Monkey King" series AEM hydrogen production system developed by EVE Hydrogen is designed based on the company's self-developed AEM membrane electrode, AEM electrolyzer, and system architecture, focusing on solving the aforementioned two major pain points of end hydrogen application.

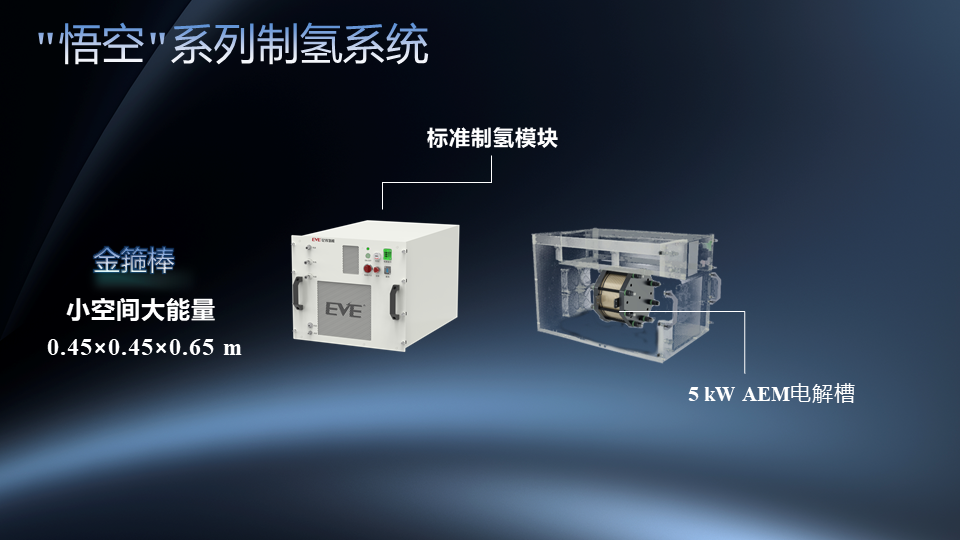

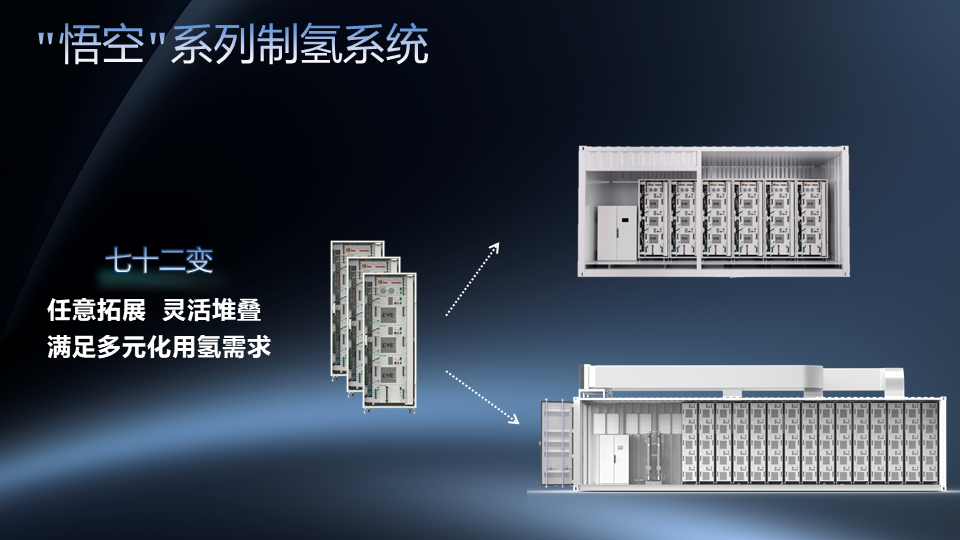

The core of the "Monkey King" system is the hydrogen production module, composed of a 5kW AEM electrolyzer and BOP (Balancing of Plant) system module unit, which can operate independently with 220V city electricity, with a hydrogen production rate as high as 1 Nm³/h and dimensions of only 0.45×0.45×0.65 m.

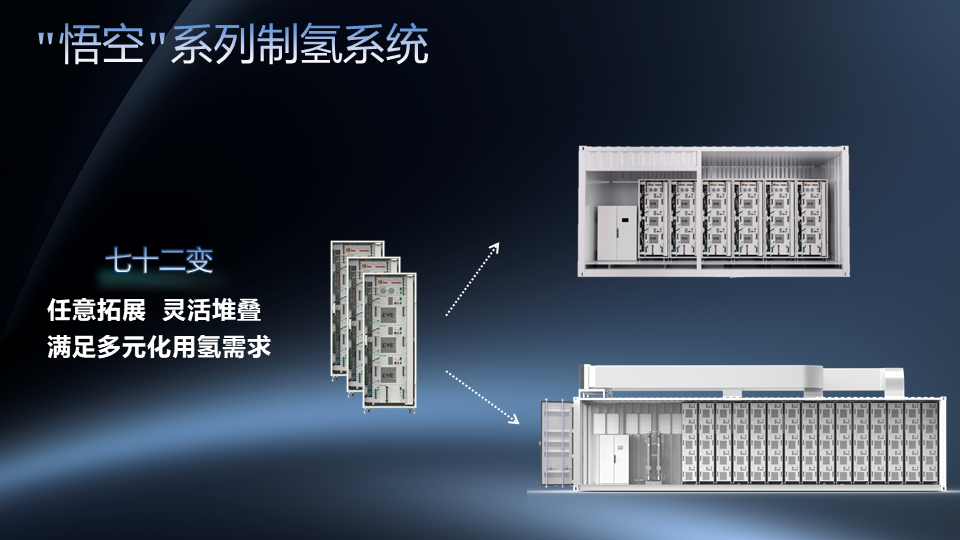

At the same time, based on this, EVE Hydrogen has introduced a cabinet hydrogen production system that integrates the power supply system, water supply system, and drying system, achieving optimal resource allocation and intelligent management. On the basis of the cabinet hydrogen production system, a container hydrogen production system has been carefully created, with auxiliary systems designed in a centralized manner, which can efficiently integrate the purification and water supply systems, while the hydrogen production modules are flexibly stacked according to actual needs, suitable for 1-200 Nm³ hydrogen production scenarios.

Both the "Monkey King" series hydrogen production cabinet and the hydrogen production container are based on the modular design concept. By modular stacking, the hydrogen production equipment, cabinet or container, is divided into multiple independent operation units, changing the traditional single electrolyzer overall structure, and significantly reducing the impact of equipment failure and downtime on users' economic benefits.

The "Monkey King" system has a significant quick start capability. Under cold conditions, it can reach the rated working condition of 100% load in only 20 minutes, and the hot start is a second-level response, which will greatly enhance the interaction between hydrogen production equipment and the power system and improve the utilization rate of energy from green electricity and valley electricity.

Taking the distributed photovoltaic off-grid coupled hydrogen production as an example, under the typical daily output curve of photovoltaics, the effective sunshine duration is about 6-8 hours a day. The "Monkey King" hydrogen production system can quickly reach the rated hydrogen production condition. The quick start capability is like equipping the green electricity to hydrogen energy process with an "accelerator," increasing the daily utilizable hours by 0.5-1 hour.

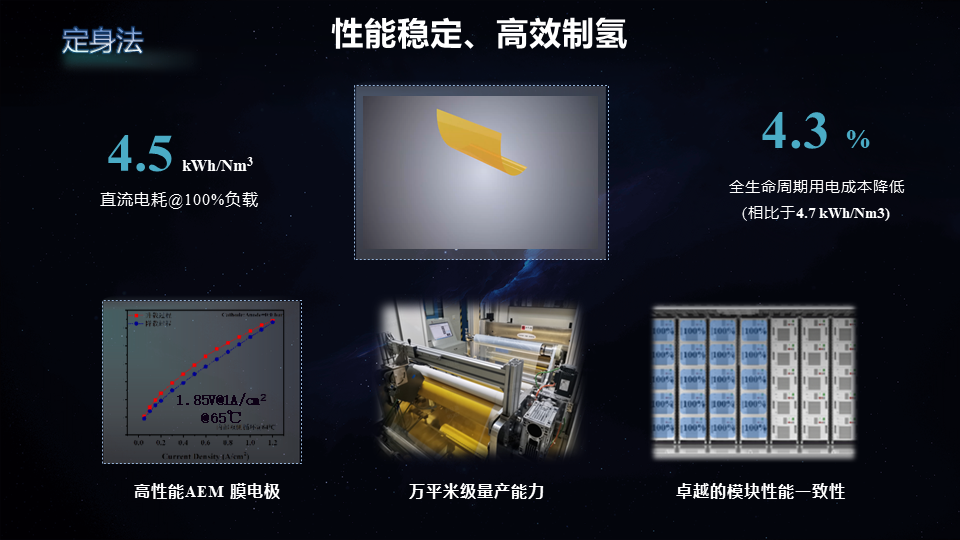

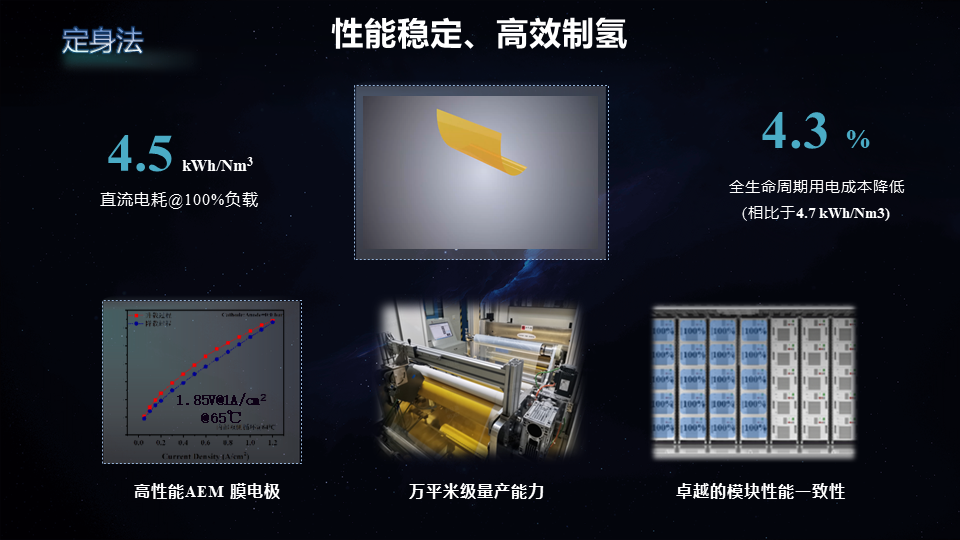

The "Monkey King" hydrogen production system has also effectively reduced the cost of hydrogen production. The system is equipped with high-performance AEM membrane electrodes developed and mass-produced by EVE Hydrogen, with a low DC electricity consumption of 4.5 kWh/Nm³. At the same time, relying on EVE Hydrogen's strong AEM membrane material manufacturing system and a production capacity of tens of thousands of square meters, the quality and continuous supply of the membrane material are effectively ensured. Therefore, compared with traditional high-energy-consuming hydrogen production equipment, the "Monkey King" system has effectively reduced the electricity cost throughout the life cycle of the equipment.

EVE Hydrogen's self-developed Alkymer® anion exchange membrane (AEM) material uses an aromatic ring as the polymer skeleton, and the pyridinium cation plays the role of ion conduction, with excellent chemical stability (derived from the stable aromatic main chain structure) and alkali resistance stability. EVE Hydrogen now has the continuous production capability of anion exchange membrane roll to roll, and has achieved the preparation of anion exchange membrane with a width of 600 mm, with an annual production capacity of 5000 square meters. It plans to upgrade the width of the anion exchange membrane (AEM) product to 1200 mm this year, with a planned annual production capacity of ≥20,000 square meters.